Company profile

Chemicals

Plant & equipment

Legionnaires' disease

Contact us

Links

Remove chlorine and/or 'organics' from your water. Activated carbon is a specialised filter media used principlally for removing chlorine or organic compounds from water. The benefit of this is a significantly improved taste and the elimination of odours, sometimes associated with a "chemical taint" to the water. Activated carbon is also used at the last stage in many water filter systems to provide a final 'polish' to the water.

Activated carbon is a specialised filter media used principlally for removing chlorine or organic compounds from water. The benefit of this is a significantly improved taste and the elimination of odours, sometimes associated with a "chemical taint" to the water. Activated carbon is also used at the last stage in many water filter systems to provide a final 'polish' to the water. Most of the activated carbon used for water treatment is made from baking crushed coconut shell until it produces a charcoal type material. This is then activated with high pressure steam, leaving the carbon with many thousands of minute active pores on it's surface. The ability of activated carbon to remove contaminates from raw water is dependent upon the length of time the water spends in contact with the media. Therefore, sizing the filters correctly is crucial for effective performance. Always take advice on this matter. Chlorine removal with carbon is a "catalytic" process in which the media does not become 'blinded' or exhausted. Instead it acts as a trigger to the de-chlorination process. The active sites on the surface of the media do eventually become blinded by other contaminants in the raw water (such as iron or colouration). This means that the media will need to be changed every 1 to 3 years (depending upon the local water quality). With organics removal, the contaminant molecules are trapped and retained in the activated sites on the carbon's surface. Eventually all of the media will become "blinded" and will need to be changed. The frequency of changing will again depend upon the level of water contamination. The effectiveness of activated carbon at removing organic compounds such as pesticides and solvents varies according to the precise nature of the contaminant. Again take advice on this matter.

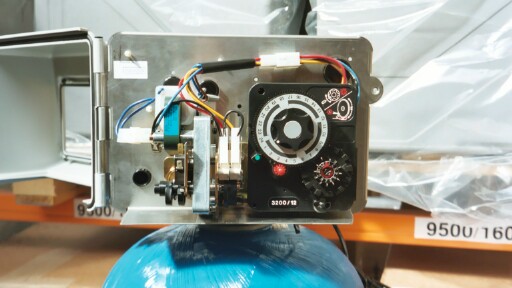

System Management and BackwashingDuring service the filter media will need to be backwashed. This is to remove the debris that accumulates on the surface of the carbon and to 'reclassify' the media to prevent 'channelling' of the water through the filter bed. The backwash and rinse cycle takes approximately 20 minutes in total.Backwashing frequency is usually controlled by a timer which will backwash the system at pre-set time intervals. Meter controlled valves can also be used which will backwash the filter media after a pre-set volume of water has been treated. For sites where there is high organic contamination of the water, the activated carbon media may need to be changed frequently. On larger systems, special tanks are available with additional side and top ports to speed up the replacement process and eliminate the need to disturb the valve and internal distribution system.

Specifying and sizingSizing of a de-chlorinator is based on a water/carbon contact time of 6 minutes, equivalent to 10 bed volumes per hour. De-colouration may require a longer contact time. So more filter media or a slower filter rate may be needed. Larger systems using steel vessels and service valve controllers are available to order.

Technical Details and Model NumbersAvailable on request.NB To prevent damage to the vessel these filters must be protected from negative pressure from the drain or supply. A vacuum relief valve is recommended on the inlet supply and is supplied with all vessels from 770mm diameter upwards. |