Company profile

Chemicals

Plant & equipment

Legionnaires' disease

Contact us

Links

Remove dissolved Iron, Manganese and turbidity.Contamination of water by heavy metals can be solved by their catalytic removal. This requires the use of specific filter media. These media can be mixed in a multi-layer bed which, when combined with an appropriate backwash or regeneration system, can be tailored to solve a wide range of specific metal and non-metallic contaminant problems.Iron and Manganese (plus Aluminium and Hydrogen Sulphide) removal Iron and Manganese can be removed with a catalytic filter media which uses oxygen in the water to convert the metal ions from the soluble to an insoluble form. The insoluble precipitate is then filtered out onto the surface of the media. Depending on the composition of the supply water a choice of filter media can be used.

Iron and Manganese can be removed with a catalytic filter media which uses oxygen in the water to convert the metal ions from the soluble to an insoluble form. The insoluble precipitate is then filtered out onto the surface of the media. Depending on the composition of the supply water a choice of filter media can be used. BIRM filter media is the lowest cost option and just requires backwashing with the supply water to clear the bed. However the operating parameters for BIRM filters are quite narrow and specific. FILOX media filters have much higher surface activity and wider operating parameters. FILOX can also be used for removing Hydrogen Sulphide. For very high flow industrial systems Manganese Greensand filters can be used. However these require regeneration with solutions of Potassium Permanganate which adds to the complexity of the process and has a number of COSHH implications. Most Iron and Manganese removal systems can remove Aluminium provided that the pH is elevated and air is injected. (See below)

Turbidity Removal General turbidity removal at high flows can be achieved satisfactorily down to low micron levels using a multi media filter with a layered bed of gravel, filter sand, garnet, and anthracite or Filter AG media. Other specialist media may need to be added to the filter bed to improve 'polishing' with certain types of water.

General turbidity removal at high flows can be achieved satisfactorily down to low micron levels using a multi media filter with a layered bed of gravel, filter sand, garnet, and anthracite or Filter AG media. Other specialist media may need to be added to the filter bed to improve 'polishing' with certain types of water.

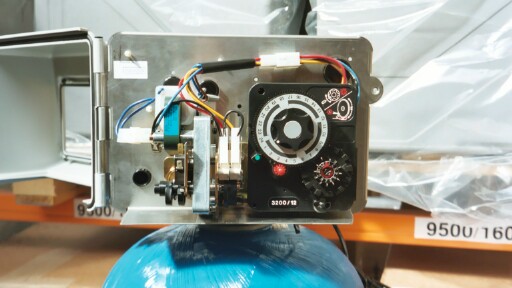

System Management and BackwashingIn order to remove accumulated deposits from the filter bed, the water flow through the filter is reversed (backwashed). Water is run to drain at a high flow rate to separate the filter media from the deposits. The control valve completes the backwash cycle automatically at the intervals and times set during installation. Backwash and fast rinse times are set for 20 minutes per cycle. These can be altered to suit individual conditions.

Specifying and Sizing BIRM Operating parameters :

BIRM Operating parameters :

Temperature :

BIRM, Greensand and Multi-Media Filter Systems include service and drain line flow controllers. NB Backwash flow per vessel is twice the service flow, therefore where possible use two or more small units instead of one large one.

Technical Details and Model Numbers for BIRM/Manganese Greensand Systems and Multi Media Filters.Available on requestFILOX-R filter systems for removal of Iron, Manganese and Hydrogen SulphideIncludes service and drain line flow controllers. NB Backwash flow on all systems is greater than service flow.Operating perameters :

Temperature:

Technical Details and Model NumbersAvailable on request.NB To prevent damage to the vessel these filters must be protected against negative pressure from the drain or supply. A vacuum relief valve is recommended on the inlet supply and is supplied with all vessels from 370mm diameter upwards. |